Assessment 2 : The Ferrari 250 GTO

| L |

| T |

| T |

| S |

As we were only a group of four it was expressed that the entirety of the Ferrari was not needed to be completed as the marking was based on the portion that you were responsible for, however it was still a desire of our group to attempt to finish the Ferrari in its entirety.

1.

The

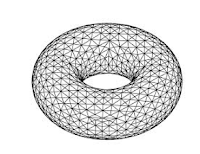

first step was to create the template of the Ferrari. The initial program 123D Make was no longer available

however it was readily suggested that another program Slicer for Fusion 360 was suitable and we were able to get started

quickly in class. We downloaded the model, imported it into the program and

began exploring the realms of Digital

Making.

2.

It

came to our attention that the Ferrari must be a particular size/scale as it

had to fit inside the BERG (Built Environment Roving Gallery), so we measured this

box and ensured our Ferrari would fit. As part of creating the template we also

had the option of what thickness of material to use as well as how many waffles we wanted running horizontally

and vertically. We decided on 18x22

waffles in 3mm MDF with a 3.1mm gap to allow the pieces to fit

tightly. After exporting the model, we had a to clean up the line work on adobe

illustrator in order for the Ferrari to print correctly. This was tedious as

there was a lot of line work however ensured a precise model with no weak

appendages.

3.

Next

step involved printing the model.

This was a new experience as we were using the laser cutters, which I had never personally used before. It was

easier than expected and our pieces came out nicely. Assembling the pieces proved

much more difficult. The amount of waffles we had was overwhelming and although

it made for an extremely precise model, it took a long time to assemble. This

was not helped through the tight fit that we also wanted by only allowing for

1mm of wiggle. The template required a lot of force to slot the pieces together.

But once assembled it did not disappoint.

6.

It

was suggested to use trace paper to

fold over the template in order to guide where the skin would need to be

shrunk, curved etc. This was very helpful as it allowed me to understand where

to hammer the piece rather than just use my eye. So I began hammering.

7.

This

was the finished product. My aluminum became very thin and difficult to mold; I

would have liked to make it a tight fit as in allow it to sit on the template.

This could have been done by incorporating parts of the hood into the piece etc.

But overall it sits quite nicely in comparison to the original Ferrari.

This comment has been removed by the author.

ReplyDeleteGreat work Henry. Nice story from start to finish. I would like to drive in that Ferrari LOL.

ReplyDeleteFinal grade = 82 Distinction

Total grade = 45 FAIL

Well done, time for a well earned rest.